The ALEX HX10 pump station is designed for small solar thermal installations with a nominal collector area of up to 12 m2 (e.g., 5 KS2100F TLP AC collectors). The high-efficiency circulating pump used allows the stringent requirements of the ErP Directive for maximum electricity consumption to be met. The ALEX HX10 pump station, from the design stage to its production, is developed at Hewalex on the basis of many years of in-house experience, but above all on the basis of the practical experience of contractors and users of solar thermal installations.

The latest generation of electronically speed-controlled circulation pumps have several times lower electricity consumption than older pumps operating at constant speed. The ALEX HX10 pump station includes a circulating pump whose operation can be controlled according to the latest control standards (iPWM signal, iPWM2). This allows the use of advanced algorithms to manage the operation of solar thermal systems, based on constant measurements of temperature and flow in the operating circuit. The energy efficiency of the entire solar thermal system is the highest of all heat sources. For every 100 W of heat generated, 1-2 W of electricity is usually sufficient.

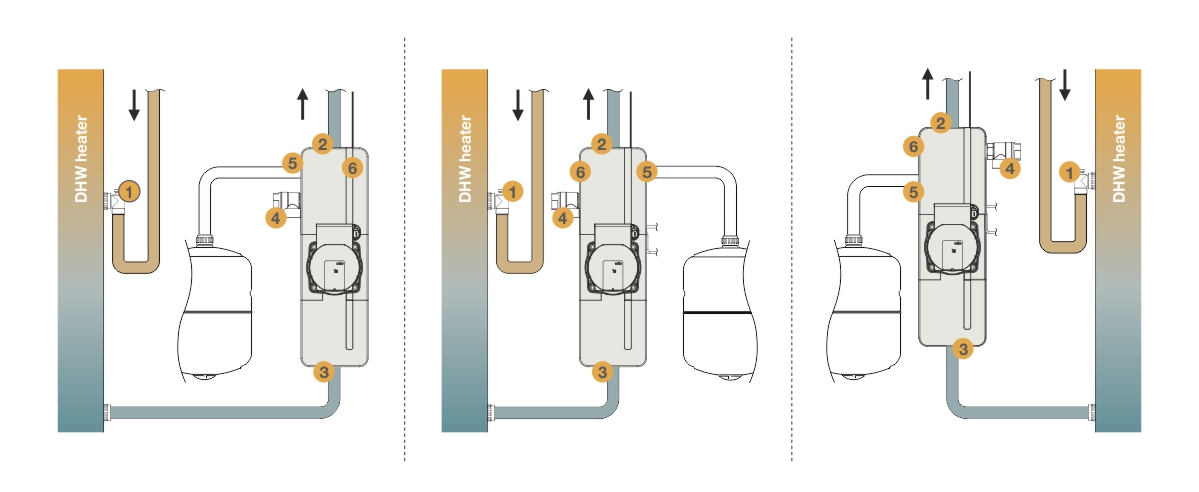

The compact dimensions allow the pump station to be installed in a small space, and the modular design makes installation work easier and less time-consuming. It is also possible to choose to connect the solar circuit to the left or right of the pump station, or bilaterally. This provides the freedom to choose where to install the pump station, regardless of the location of the domestic hot water storage tank. Also, the pressure gauge can be freely positioned on the left or right side of the unit, depending on access for convenient reading of the system pressure. A solar thermal system vent installed at the inlet to the hot water storage tank coil is an extremely important addition.

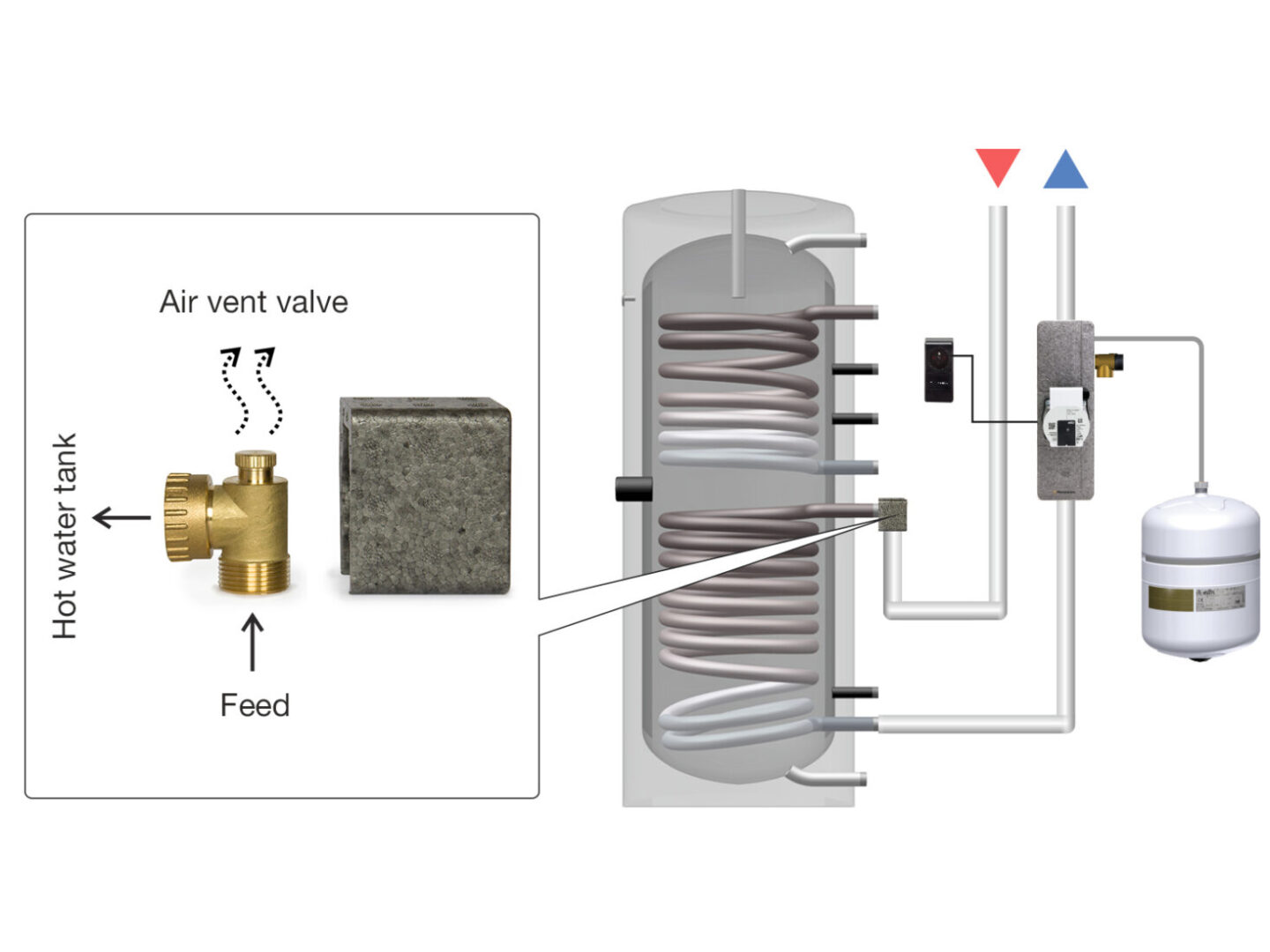

The ALEX HX10 pump station includes an additional T-piece with air vent made according to a new concept. This ensures effective venting of the solar thermal system during initial commissioning and during servicing. Air capture takes place within the coil heat exchanger where, due to the cross-section of the pipes, the glycol flow rate is lowest. The air bubbles here therefore have a greater ability to float upwards towards the vent. The tee is made of brass and has thermal insulation. Venting is at once easily accessible, convenient and quick to carry out.

Learn more

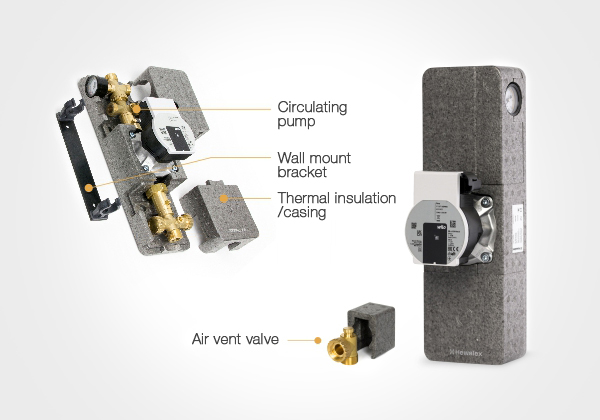

- highly efficient circulating pump that complies with the ErP directive (from August 2015),

- compact design integrating all components in a polypropylene housing providing thermal insulation,

- low flow resistance throughout confirmed in tests, significantly lower than standard devices of this type,

- simple installation – bracket fixed with two screws,

- easy filling and flushing of the system – two drain valves as standard,

- quick and reliable bleeding of the system – connection tee with air vent, mounted at the upper coil connection – the coil acts here as a deaerator,

- can be combined with any solar controller operating a PWM signal-controlled pump,

- can be fitted with additional components such as a temperature sensor and pressure switch or electronic flow meter.

The solar supply is connected via a tee with vent (1) included in the scope of supply of the ALEX HX10. The return to the solar thermal collectors should be connected to one of the connections at the top of the pump station (2), while the return from the hot water storage tank coil should be connected to one of the lower outlet connections (3). The safety valve (4), as well as the expansion vessel connection (5) and pressure gauge (6), can be connected to the pump station, depending on its location in relation to the hot water storage tank.

Cat. No.:

71.34.08

Height:

375 mm

Width:

115 mm

Depth:

130 mm

Nominal flow rate:

10 l/min.

Max. head at zero point (0 l/min.):

7,0 mH2O

Max. head for nominal flow:

ok. 6,0 mH2O

Maximum operating temperature:

110°C

Maximum operating pressure:

6 bar

Ports:

3/4″

Warranty period:

2 years

Cat. No.:

71.34.08

Height:

375 mm

Width:

115 mm

Depth:

130 mm

Nominal flow rate:

10 l/min.

Max. head at zero point (0 l/min.):

7,0 mH2O

Max. head for nominal flow:

ok. 6,0 mH2O

Maximum operating temperature:

110°C

Maximum operating pressure:

6 bar

Ports:

3/4″

Warranty period:

2 years